Building the World: The Role of Machining in Global Manufacturing

In the vast tapestry of global manufacturing, machining stands as a critical pillar that supports and shapes the industry. From the smallest components in everyday gadgets to massive parts in industrial machinery, the precision and efficiency imparted by machining are indispensable. As globalization continues to shrink our world, machining becomes even more crucial, driving innovation and maintaining the quality standards required by diverse markets.

The Importance of Machining in Manufacturing

Machining is the process of transforming raw materials into precise, finished products through controlled material-removal processes. It encompasses operations such as cutting, drilling, milling, and turning, and it is essential for creating the intricate components found in modern technology. Without machining, the seamless operation of mechanical systems ranging from household appliances to aerospace equipment would be virtually impossible.

The role of machining in manufacturing is multi-faceted. First, it allows for the mass production of complex parts with unparalleled accuracy. This capability is fundamental in industries such as automotive, aerospace, and electronics, where even the slightest deviation can result in significant functional deficiencies. The repeatability and precision of machining ensure that each component meets rigorous specifications, thus maintaining product integrity and safety.

Precision and Efficiency: The Hallmarks of Machining

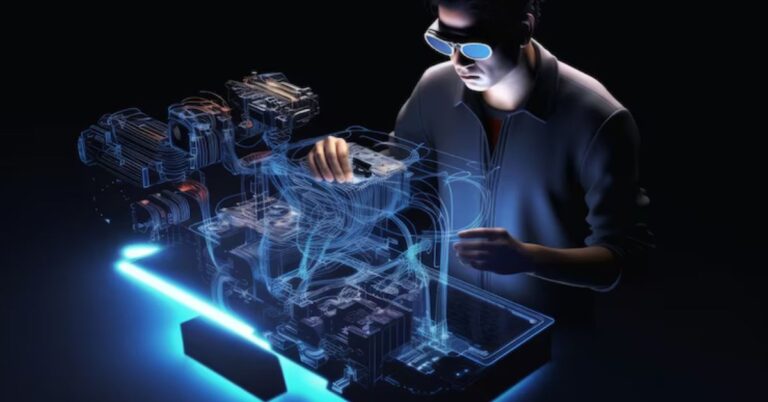

The demand for precision in manufacturing has never been higher, given the complexity of modern products and the competitive nature of the global market. Machining excels in this realm, offering unmatched levels of detail and accuracy. Advanced computer numerical control (CNC) machines have revolutionized the industry, enabling the production of intricate parts with minimal human intervention. These machines are capable of executing complex designs with a high degree of repeatability, thus reducing errors and waste.

Efficiency in machining is achieved through various technological advancements. High-speed machining techniques, for instance, significantly reduce production times while maintaining precision. Additionally, the integration of automation and robotics in machining processes further enhances efficiency, allowing for continuous production cycles that maximize output and minimize downtime.

The Role of Equipment Manufacturers

Equipment manufacturers play a pivotal role in the advancement of machining technology. By developing and providing cutting-edge machinery and tools, they enable industries to push the boundaries of what is possible in manufacturing. These manufacturers invest heavily in research and development to create machines that are not only more precise but also more environmentally friendly and energy-efficient.

The collaboration between equipment manufacturers and the machining industry drives innovation, leading to new machining processes and technologies that enhance capabilities across various sectors. This partnership is vital for maintaining the competitive edge of manufacturers in a rapidly evolving global landscape.

Future Prospects of Machining in Global Manufacturing

Looking to the future, the prospects of machining in global manufacturing are bright and promising. As industries continue to evolve, the demand for new and improved machining technologies will grow. Emerging trends such as the Internet of Things (IoT), Industry 4.0, and additive manufacturing are set to reshape the machining landscape, introducing smart machines and integrated systems that enhance connectivity and data management.

Additive manufacturing, while often seen as a competitor to traditional machining, actually complements it by allowing for the production of complex geometries that were previously unattainable. The convergence of additive and subtractive manufacturing techniques will open new avenues for innovation, offering manufacturers greater flexibility and efficiency.

Moreover, the push towards sustainability in manufacturing will influence the future of machining. There will be a greater emphasis on developing processes that minimize environmental impact, such as reducing energy consumption and recycling materials. This shift will require continuous innovation in machining techniques and equipment.

In conclusion, machining is and will remain a cornerstone of global manufacturing. Its ability to deliver precision and efficiency is unmatched, making it an essential component in the production of the complex and diverse products that define modern life. As technology advances and the world becomes more interconnected, machining will continue to adapt and thrive, driving progress and building the future of manufacturing.

Keep an eye for more news & updates on Hip Hop!